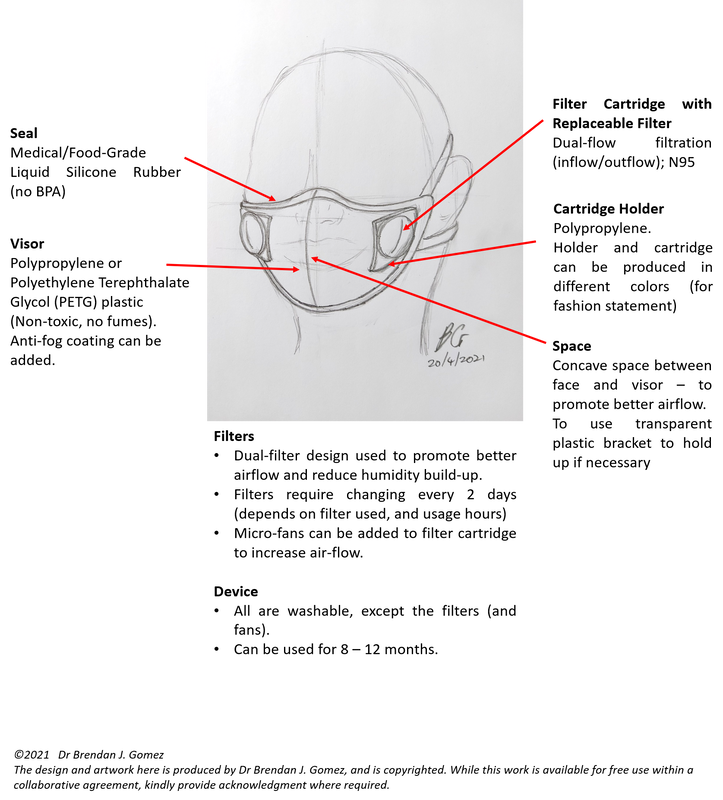

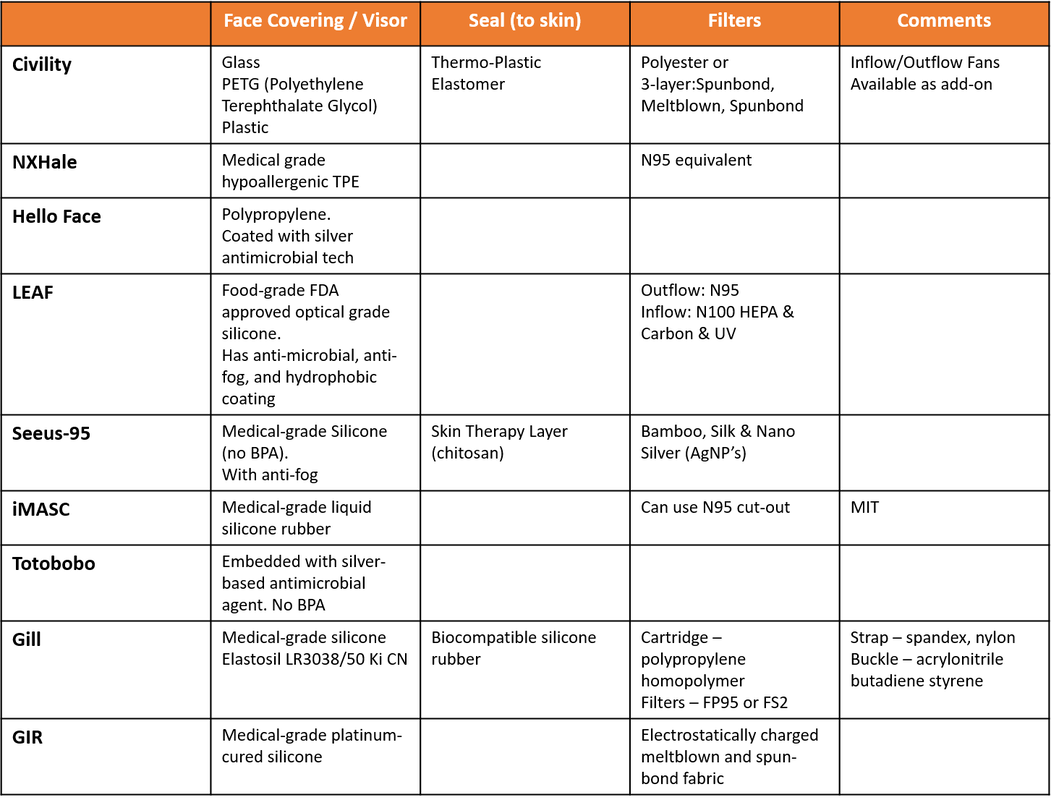

Mask Materials for Consideration for SAFER Mask

Materials currently being used globally in other similar masks

Note: Table above only contains information published on each mask developer's website. Some information may be missing or not provided on their respective sites.

Materials Selection / Engineering

We want to determine the following for the visor and seal components:

We want to determine the following for the visor and seal components:

- Strength & Flexibility - the ability of the material to flex to create the concave shape of the visor, and to retain shape for the duration of use

- Durability - the ability of the material to last more than 8 months without compromising safety of the child

- Toxicity - to ensure that materials used does not leach any toxins that could enter the airways or skin during long-term use of the mask (we estimate usage of device at 6-hours per-day for children and 8-hours per-day for adults)

- Fit - the ability of the material used in the seal to be flexible enough to conform to different face structures to provide needed fit to reduce air leakage. Need a shape, texture and softness that can conform while providing comfort

- Affordability - materials used must be cost-efficient to ensure affordability for every child

Filters for Prototype Mask

Polypropylene

|

There are many types of non-woven polypropylene. The most common are spunbond, meltblown and spunlace materials.

Meltblown polypropylene is used as the middle layer of many certified medical masks and in the manufacture of respirators such as N95s. It is important to recognize that not all interfacing is polypropylene. Many brands are polyester or polyester-rayon blends. This is a completely different material. In the retail market, interfacing is sometimes sold as a fusible product. This means that it is pre-glued to help with accurate placement before it is stitched into place. These pre-glued fabrics should not be used for face coverings because the glue may affect filtration and breathability. Some reusable shopping bags made from spunbond have a shiny plastic coating. These are not breathable and should not be used. https://theconversation.com/polypropylene-the-material-now-recommended-for-covid-19-mask-filters-what-it-is-where-to-get-it-149613 |

|

Cotton

The filtration efficiency of cotton fabrics increases in humid conditions because cotton is hydrophilic, meaning it likes water. By absorbing small amounts of the water in a person’s breath, cotton fibers create a moist environment inside the fabric. As microscopic particles pass through, they absorb some of this moisture and grow larger, which makes them more likely to get trapped

https://www.nist.gov/news-events/news/2021/03/study-indicates-humidity-breath-makes-cotton-masks-more-effective-slowing

https://www.nist.gov/feature-stories/masks-under-microscope

https://www.nist.gov/news-events/news/2021/03/study-indicates-humidity-breath-makes-cotton-masks-more-effective-slowing

https://www.nist.gov/feature-stories/masks-under-microscope

Vacuum Cleaner Filters

|

In tests at Missouri University and University of Virginia, scientists found that vacuum bags removed between 60 percent and 87 percent of particles.

But some brands of vacuum bags may contain fiberglass or are harder to breathe through than other materials, and shouldn’t be used. Ms. Wu used a bag by EnviroCare Technologies, which has said it does not use fiberglass in its paper and synthetic cloth bags. www.nytimes.com/article/coronavirus-homemade-mask-material-DIY-face-mask-ppe.html https://www.weforum.org/agenda/2020/07/covid19-coronavirus-infection-protection-mask-material |

|

Using Silver as Anti-Microbial Agent

We need to approach this with caution as silver is toxic to human cells.

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6359645/

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6359645/

The Gold-Standard for Comparison: LEAF

Design to Production of Face Mask

A guide